Welcome to the Beckett AFG Burner Manual. This guide provides essential information for installing, operating, and maintaining your burner. Designed for homeowners and technicians, it covers key aspects of installation, operation, maintenance, and troubleshooting. Always follow safety guidelines to ensure optimal performance and longevity.

Overview of the Beckett AFG Burner

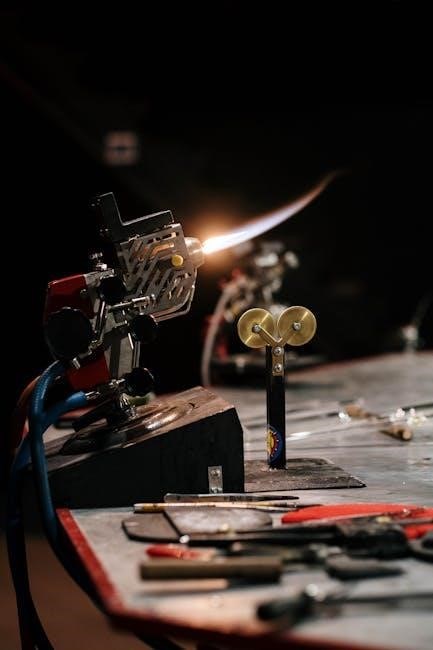

The Beckett AFG Burner is a high-efficiency oil burner designed for residential and small commercial heating applications. It is compatible with various fuels, including heating oil and renewable biofuels, offering flexibility and environmental benefits. The burner features a range of firing rates (0.40 to 3.00 GPH) and is equipped with advanced combustion technology for optimal performance. It is designed to work seamlessly with different heating systems, ensuring reliable and consistent heat output. The AFG Burner is known for its durability and ease of maintenance, making it a popular choice among homeowners and professionals. Its compact design and user-friendly interface simplify installation and operation, while its safety features, such as combustion air kits, enhance overall safety and efficiency.

Key Features and Benefits of the AFG Burner

The Beckett AFG Burner offers numerous key features that enhance its performance and usability. One of its standout features is its compatibility with both traditional heating oil and renewable biofuels, making it an environmentally friendly option. The burner is designed with a wide firing rate range of 0.40 to 3.00 GPH, allowing it to suit various heating needs. It also incorporates advanced combustion technology, which ensures efficient fuel usage and reduces emissions. Additionally, the AFG Burner is equipped with a universal adjustable flange, simplifying installation across different heating systems. Its compact design and lightweight construction make it easy to handle and install. Furthermore, the burner’s robust construction and durable components contribute to its long lifespan. These features collectively provide reliable, efficient, and safe heating solutions for homeowners and businesses alike.

Safety Precautions and Warnings

Potential hazards include fire, smoke, and asphyxiation risks. Incorrect installation or misuse can cause death, severe injury, or property damage. Always follow manual instructions carefully.

General Safety Guidelines for Installation and Operation

Always adhere to safety guidelines to prevent accidents. Ensure proper installation by a qualified technician, following manual instructions. Disconnect power before servicing to avoid electrical shock. Use specified parts and never modify the burner, as this can void warranties and cause malfunctions. Keep the area well-ventilated to prevent carbon monoxide buildup. Regularly inspect the burner and surrounding equipment for damage or wear. Follow all local safety codes and manufacturer recommendations. Never operate the burner if it’s damaged or improperly installed. Keep flammable materials away from the burner. Proper maintenance ensures safe and efficient operation, protecting both people and property from potential hazards.

Potential Hazards: Fire, Smoke, and Asphyxiation Risks

The Beckett AFG Burner poses risks of fire, smoke, and asphyxiation if not installed or maintained correctly. Improper installation can lead to fuel leaks, igniting fires or producing toxic smoke. Inadequate ventilation increases carbon monoxide levels, risking asphyxiation. Ensure all connections are secure and ventilation systems function properly. Never override safety features or bypass controls, as this can cause uncontrolled combustion. Regular inspections by professionals are crucial to identify and mitigate potential hazards. Always follow the manual’s guidelines to minimize these risks and ensure safe operation. Proper precautions protect users from severe injury or property damage.

Electrical Safety: Disconnecting Power Before Servicing

Electrical safety is critical when servicing the Beckett AFG Burner. Always disconnect power before performing any maintenance or repairs to prevent electric shock. Turn off the main power switch and verify that the burner is completely de-energized. Never attempt to service the burner while it is powered on or in standby mode. Use a multimeter to confirm the absence of voltage at the burner terminals. Failure to disconnect power can result in severe injury or death. Ensure all capacitors are discharged if you are handling internal components. Follow proper lockout/tagout procedures to ensure your safety and the safety of others working on the system. Electrical safety precautions are non-negotiable and must be strictly adhered to at all times.

Installation Requirements and Preparation

Proper installation is crucial for safe and efficient burner operation. Ensure the site is prepared, and the burner is correctly assembled and inspected. Follow all guidelines carefully to avoid hazards and ensure compliance with local codes and manufacturer specifications.

Site Preparation for AFG Burner Installation

Proper site preparation is essential for safe and efficient installation of the Beckett AFG Burner. Ensure the installation area is clean, well-ventilated, and free from flammable materials. The burner must be installed on a level surface, and the surrounding area should be clear of obstructions. Properly install the outside air kit if required, following the manufacturer’s instructions. Ensure all electrical connections are securely made and meet local codes. The burner should be mounted correctly, with the air tube pitched downward unless specified otherwise. Always use approved parts and follow safety guidelines to avoid hazards. Improper installation can lead to performance issues or safety risks. Consult the manual for specific requirements and ensure compliance with local regulations and manufacturer recommendations.

Preparing the Burner for Installation

Before installing the Beckett AFG Burner, ensure the unit is properly prepared. Unpack the burner carefully and inspect for any shipping damage. Do not remove the air guide from the AFG chassis, as this can void the warranty and affect performance. Verify the correct air tube combination is installed, as specified in the manual. Check the Z dimension (distance from the nozzle to the head) and adjust if necessary to ensure proper combustion. Inspect the electrodes and ensure they are correctly aligned. If using a baffle, install it according to the manufacturer’s instructions. Secure all electrical connections and ensure they match the wiring diagram. Finally, test the burner’s operation before proceeding with installation to confirm everything functions correctly. Proper preparation ensures a safe and efficient installation process.

Inspecting and Preparing the Installation Site

Ensure the installation site is clean, level, and free from obstructions. Verify that the area meets local building codes and regulations. Check for adequate clearance (minimum 1 inch on all sides) to allow proper airflow and servicing. Inspect the floor or platform to ensure it is level and sturdy enough to support the burner’s weight. Ensure the surrounding area is well-ventilated to prevent the accumulation of flammable vapors or combustion byproducts.

Verify that all necessary utilities (electricity, fuel supply) are available and properly connected. Inspect the chimney or venting system for blockages or damage. If using an external air kit, ensure it is installed according to the manufacturer’s instructions to prevent burner malfunction. Proper site preparation ensures a safe and efficient installation process.

Operating the Beckett AFG Burner

Start the burner by setting the thermostat above room temperature and closing the line voltage switch. Monitor performance and adjust settings as needed for optimal efficiency and safety.

Startup and Initial Adjustment of the Burner

Starting the Beckett AFG burner involves setting the thermostat above room temperature and closing the line voltage switch. If the burner doesn’t start immediately, reset the safety switch on the primary control. Ensure proper combustion by adjusting the air flow and fuel settings according to the manual. Regularly inspect the electrodes and clean them if necessary. Always refer to the manual for specific startup procedures and safety precautions to ensure efficient and safe operation. Proper initial adjustments are crucial for optimal performance and longevity of the burner.

Adjusting Combustion and Performance Settings

Proper adjustment of combustion and performance settings is critical for optimal operation. Start by ensuring the Z dimension, the distance from the nozzle face to the head, matches specifications using a Beckett T500 gauge. Refer to firing rate tables in the manual to set the correct fuel flow. The Low Fuel Rate Baffle (LFRB) must be installed as specified to maintain performance and safety. Adjust the air tube position to achieve the recommended airflow, ensuring proper combustion. Regularly monitor emissions and performance metrics to ensure efficiency. Always follow the manual’s guidelines for adjustments to avoid hazards and maintain warranty compliance. Proper settings ensure reliable operation and minimize emissions. Professional servicing is recommended for complex adjustments.

Maintenance and Service

Regular maintenance ensures the longevity and efficiency of your Beckett AFG burner. Schedule annual professional inspections to clean components and check for wear. Replace parts like electrodes and gaskets as needed. Use only Beckett-approved parts to maintain performance and safety. Proper upkeep prevents malfunctions and extends burner life, ensuring reliable heating performance. Always refer to the manual for specific maintenance instructions and guidelines.

Routine Maintenance Tasks for Optimal Performance

Regular maintenance is crucial for ensuring the Beckett AFG burner operates efficiently and safely. Inspect and clean the electrodes annually, as dirty or misaligned electrodes can disrupt ignition. Clean the air tube and combustion chamber to prevent residue buildup, which may hinder performance. Check fuel lines for leaks or blockages and ensure proper connections. Verify combustion settings and adjust as needed to maintain optimal firing rates. Replace worn-out parts, such as gaskets or filters, to prevent leaks or reduced airflow. Schedule annual professional inspections to address hidden issues and ensure compliance with safety standards. Proper maintenance prevents malfunctions, reduces energy consumption, and extends the burner’s lifespan. Always use Beckett-approved replacement parts to maintain warranty validity and performance quality.

Replacement Parts and Upgrades for the AFG Burner

Replacing parts on the Beckett AFG burner ensures optimal performance and safety. Always use Beckett-approved components to maintain warranty validity and reliability. Common replacement parts include electrodes, air tube combinations, and combustion heads. Check the manual for specific part numbers and compatibility. Upgrades, such as biodiesel-compatible kits, are available for modern fuel requirements. Never alter the burner’s design or use unauthorized parts, as this can void certifications and compromise safety. Regularly inspect and replace worn-out gaskets, seals, and filters to prevent leaks and maintain efficiency. For upgrades, consult Beckett’s technical support to ensure compatibility and proper installation. Properly replacing and upgrading parts extends the burner’s lifespan and ensures reliable operation.

Troubleshooting Common Issues

Identify symptoms of burner malfunctions, such as improper ignition or uneven flame. Check for common issues like clogged nozzles or faulty electrodes. Refer to the manual for solutions, ensuring electrical and combustion systems are functioning correctly. Contact Beckett technical support for persistent problems.

Identifying and Resolving Common Problems

Common issues with the Beckett AFG Burner include improper ignition, uneven flames, or reduced efficiency. Check for clogged nozzles, faulty electrodes, or incorrect air-to-fuel ratios. Ensure proper electrical connections and verify fuel supply. Refer to the troubleshooting section for step-by-step solutions. If issues persist, consult the manual or contact Beckett technical support for assistance. Regular maintenance and adherence to safety guidelines can prevent many problems. Always follow manufacturer instructions to resolve issues safely and effectively.

Diagnostic Steps for Burner Malfunctions

Diagnosing burner malfunctions involves systematic checks. First, ensure the fuel supply is adequate and properly filtered. Verify electrical connections and controls for integrity. Check combustion air availability and ensure vents are unobstructed. Inspect electrodes for wear or misalignment and clean or replace them as needed. Measure the air-to-fuel ratio and adjust if necessary. Refer to the manual’s troubleshooting section for specific error codes or symptoms. If issues persist, consult the manual or contact Beckett technical support for professional assistance. Regular maintenance and adherence to safety protocols can help prevent malfunctions and ensure optimal performance.

Additional Resources and Support

For further assistance, visit the official Beckett website for the complete AFG Burner Manual or contact their technical support team for professional guidance and troubleshooting.

Accessing the Full Beckett AFG Burner Manual

To access the complete Beckett AFG Burner Manual, visit the official Beckett website or authorized distributors. The manual is available for download as a PDF, ensuring easy access to detailed instructions. For specific models like the Weil-McLain Gold Oil Series, the manual can be found under the “Manuals” section. Additionally, platforms like ManualsLib offer the Beckett AFG Oil Burner Instruction Manual (12 pages), providing comprehensive guidance on installation, operation, and maintenance. Always refer to the official manual for accurate information to ensure safe and efficient use of your Beckett AFG Burner.

Contacting Beckett Technical Support

For assistance with your Beckett AFG Burner, contact Beckett Technical Support. Visit their official website at beckettcorp.com/support for resources, including troubleshooting guides and FAQs. For direct inquiries, call their toll-free number at 1-800-645-2876. Ensure you have your burner’s serial number ready, located on the Underwriters Laboratories label on the rear of the burner. Beckett also offers online training and support materials to help users and technicians resolve issues efficiently. Their customer service team is dedicated to providing prompt and professional assistance to ensure optimal performance and safety of your burner.